Rockrebar.com

FRP-Rebar Manufacturers Council ![]()

BASALT FRP (BFRP)

ASTM International Designation D8505/D8505M-23

2681 N.E. 4th AVE

POMPANO BEACH, FL 33064

ph: 954-803-9206

alt: 954-270-9000

bill

- Rockrebar® News

- Articles

- About CBF (continuous basalt fiber)

- PRODUCT VIDEOS

- Rockrebar® PRODUCT project images

- RockRebar®

- What is RockRebar®

- RockCages™

- RockStirrups®

- RockStaples® and RockFiberCrete™

- ANOUNCING RockDNA® and RockMesh® for structural reinforcement of pervious concrete

- WORLD OF CONCRETE 2016

- WORLD OF CONCRETE 2017

- Shipping information

- Technical Information

- Durability Testing

- Contact Us

- Informacion en Español

- Specifications

RockStaples® and RockFiberCrete™

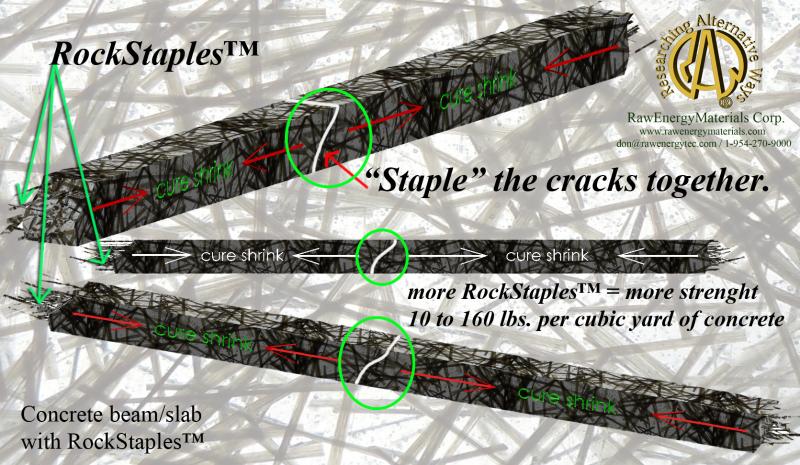

RockStaples® are an enhancement to the concept of white fiberglass “fiber create” used for some years now. Most common concretes are brittle and crack during the curing process which is normal. Concrete just cracks easily in tension; this is why rebar and mesh are placed within the concrete. Under load, the concrete takes the compressive forces and the mesh and rebar the tensile loads with both working as a system to carry shear forces. Think of RockStaples® as a refined form of tiny basalt rebar with high tensile strength and excellent adhesion that ties the cement, sand, and aggregate together at a micro level to further reduce cracking.

RockStaples™®have a density balance with concrete so they do not float and they do not sink. RockStaples® do not “clump” like fiberglass. Like the aggregate itself, RockStaples® uniformly distribute within cement paste during mixing. As a load is applied, concrete containing RockStaples® distributes the stress throughout the concrete in all directions. As Portland based concrete inevitably shrinks and cracks during the curing phase RockStaples® significantly reduce the size of the cracks. RockStaples® “staple” the concrete components together thereby raising the flexural tensile strength.

The strength enhancement RockStaples® add is purely that of the number of fibers crossing the various shrinkage stress points, more fibers = higher strength. We recommend minimum dosages of 10 pounds per cubic yard for crack control and increasing residual strength after cracking by about 3 Mpa. In cases where rebar and mesh are not possible, we have seen great success with dosages to 160 pounds per cubic yard resulting in about a 15 Mpa improvement in residual strength after cracking.

How RockStaples® raise the Flexural and Tensile strength of concrete.

• Most common concretes are brittle and crack easily in tension; this is why rebar and mesh are placed within the concrete. Under load the concrete takes the compressive forces and the mesh and rebar the tensile loads with both working as a system to carry shear forces.

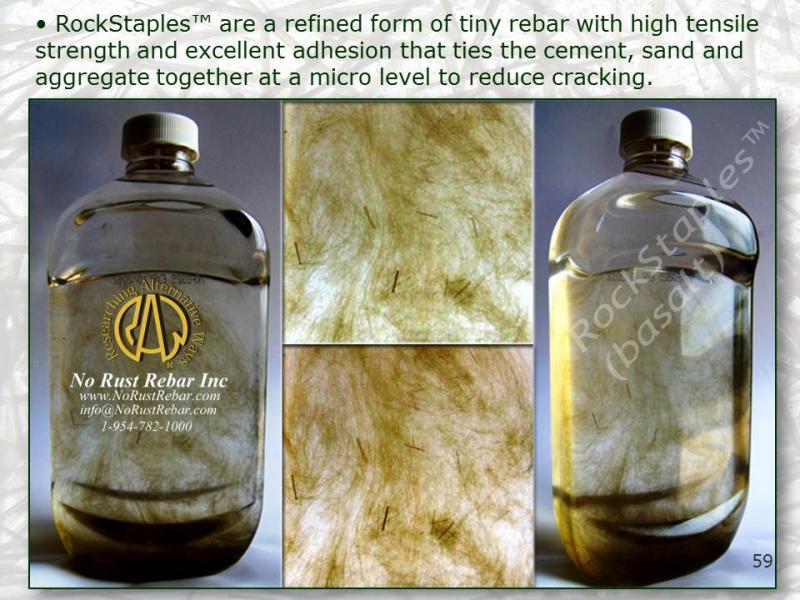

• RockStaples® are a refined form of tiny rebar with high tensile strength and excellent adhesion that ties the cement, sand and aggregate together at a micro level to reduce cracking.

• RockStaples® have a density balance with concrete so they do not float and they do not sink. RockStaples® do not “clump” like fiberglass. Like the aggregate itself RockStaples™ uniformly distribute within cement paste during mixing.

• As Portland based concrete inevitably shrinks and cracks during the curing phase RockStaples® significantly reduce the size of the cracks.

• RockStaples® “staple” the concrete components together thereby raising the flexural tensile strength.

• The strength enhancement RockStaples® add is purely that of the number of fibers across the various shrinkage cracks, more fibers = higher strength.

• We recommend dosages of 10 pounds per cubic yard for crack control and increasing residual strength after cracking by about 3 Mpa.

• In cases where rebar and mesh are not possible we have seen great success with dosages to 160 pounds per cubic yard resulting in about a 15 Mpa improvement in residual strength after cracking.

RockStaples®

As per the open civil engineering Journal 2017 11, 14 -21

Projects supported by Science and Technology Planning Project of Colleges and Universities

Summary on the investigation of RAW® brand RockStaples® (15 to 22 mm chopped basalt fiber with proprietary sizing treatment to enhance its bond with concrete).

Introduction: As a nonlinear quasi-brittle material the largest drawback of concrete is its low tensile strength which causes it to crack easily. However the application of fiber reinforced technology is proving an effective method for enhancing the strength and reducing the brittle effects of concrete especially by demonstrating a significant reduction of early shrinkage cracks as the concrete cures.

Test samples were prepared to scrutinize the mechanical properties of concrete with varying amounts of RAW® brand RockStaples® as compared to neat samples to determine the best fiber to concrete mix ratios. Testing was performed at five mix load dosages 0.5, 1, 1.5, 2, & 2.5 kg/m3. Samples were demolded after 24 hrs. Ambient temp cured 28 days then tested for: Compressive properties, flexural properties, splitting tensile properties and impact behavior of RockStaples® reinforced concrete. The results indicate that both static and impact test behaviors are significantly improved at all five mix load ranges. However in terms of performance / cost, the optimal strengthen and toughening effects were achieved @ 2 kgm/m3. Results have subsequently been verified at 4 lbs/yd3 using standard pump mix.

Concrete reinforced with RockStaples®

at dosage of 4 lbs. per yard, (2kg/m3) of RockStaples® shows significant enhancement to its compressive properties, flexural properties, splitting tensile properties and resistance to impact behavior.

RockStaples® and RockFiberCrete™

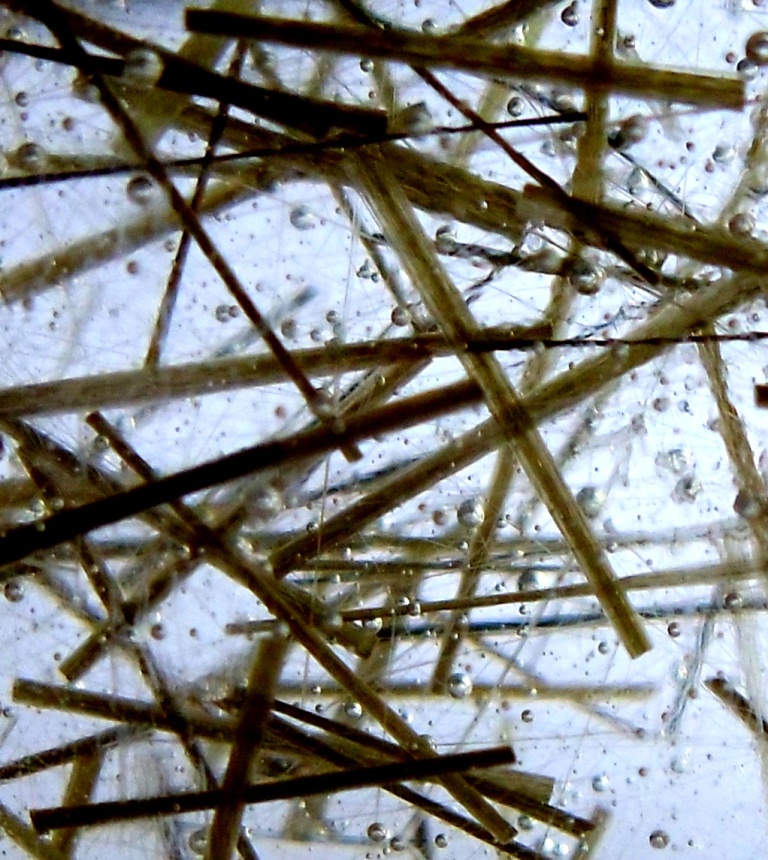

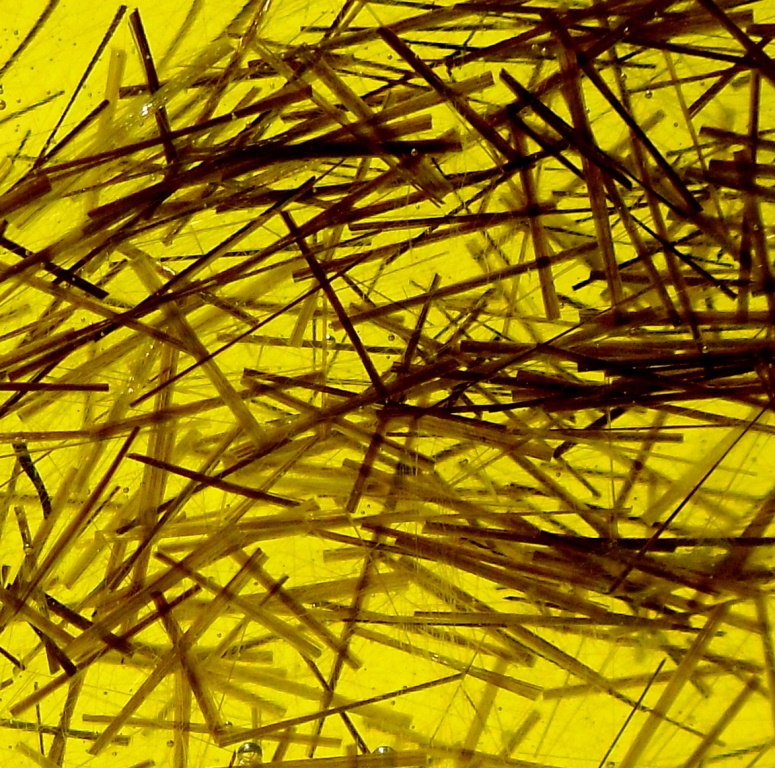

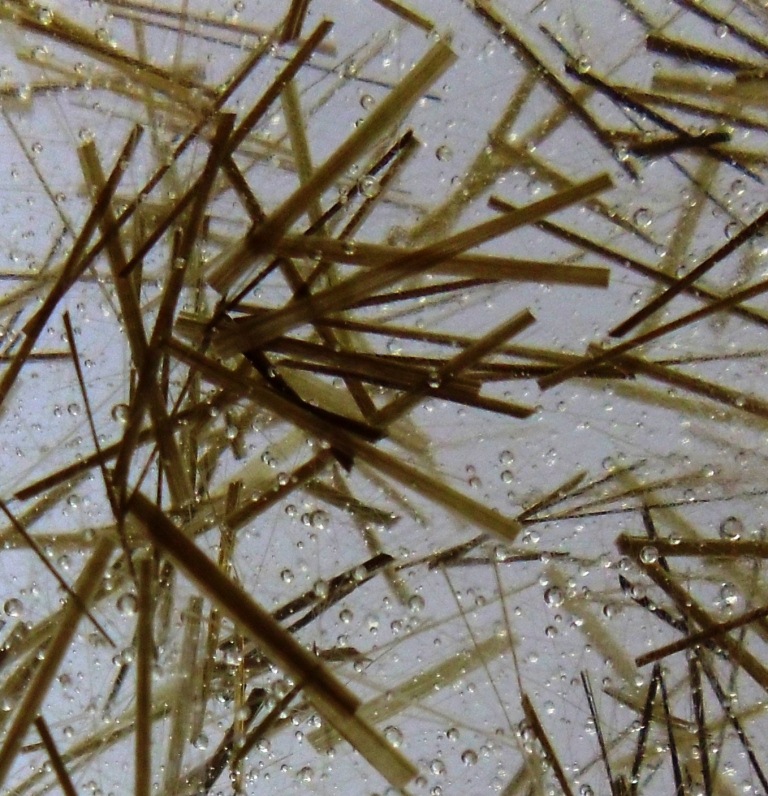

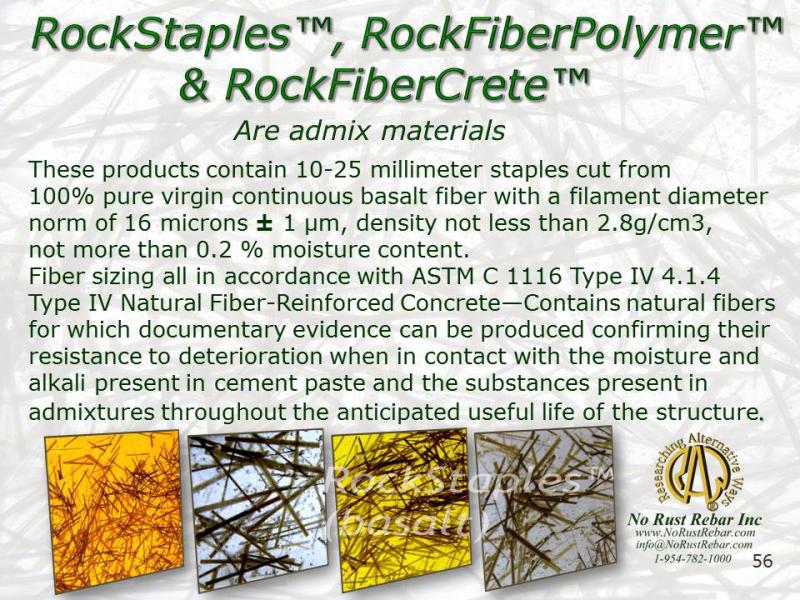

Both these products contain 10-25 millimeter staples cut from 100% pure virgin continuous basalt fiber with a filament diameter norm of 16 microns ± 1 µm, density not less than 2.8g/cm3, not more than 0.2 % moisture content and fiber sizing all in accordance with ASTM C 1116 Type IV 4.1.4 Type IV Natural Fiber-Reinforced Concrete—Contains natural fibers for which documentary evidence can be produced confirming their resistance to deterioration when in contact with the moisture and alkali present in cement paste and the substances present in admixtures throughout the anticipated useful life of the structure.

Pictured below is 16 mm x 15mm basalt staples as packaged in 50lb. bulk sacks to be individually weighed for specific reinforcement applications.

To the right RockStaples® are shown as dispersed in RockFiberCrete™ polymer admixture for crack control reinforcement of pervious concrete.

Copyright 2013 Rockrebar.com. All rights reserved.

270 S.E. 13TH STREET

POMPANO BEACH, FL 33064

ph: 954-803-9206

alt: 954-270-9000

bill